Cold-rolled steel

What is cold-rolled steel?

What are cold-rolled profiles?

Cold-rolled profiles are a wide range of shapes and dimensions manufactured from cold-rolled steel.

These profiles are used in various industrial and construction applications due to their superior mechanical properties and versatility.

Some common examples of cold-rolled profiles include beams, structural profiles, flat profiles, square profiles, and round profiles. These profiles are used in the construction of metal buildings, bridge structures, machinery, industrial equipment, metal furniture, and many other projects requiring strength and dimensional accuracy.

Properties and characteristics of cold-rolled steel

Cold-rolled steel exhibits several notable properties and characteristics that make it highly desirable in various industrial applications. Some of these properties include:

Tensile strength

It offers exceptional tensile strength, meaning it can withstand high tensile forces without deforming or breaking.

Elastic limit

The yield strength of cold-rolled steel is the maximum load it can withstand without experiencing permanent deformation.

Elongation

It has a remarkable deformation capacity without breaking, making it suitable for applications requiring flexibility and ductility.

Corrosion resistance

Depending on the type of steel used, cold-rolled steel can offer adequate corrosion resistance, especially compared to other materials such as carbon steel.

Tight dimensional tolerances

The cold rolling process produces products with precise dimensional tolerances, ensuring high precision and fit in final applications.

Acero laminado en Cold-rolled steel vs. stainless steel vs. acero inoxidable

It is important to distinguish between cold-rolled steel and stainless steel, as they have different characteristics and uses.

While both types of steel have multiple applications, cold-rolled steel is more common in those where dimensional accuracy and specific mechanical properties are required.

On the other hand, stainless steel is used in applications that require corrosion resistance, such as the manufacture of kitchen utensils, medical equipment, structural components exposed to corrosive environments, among others.

What is the cold rolling process?

The cold rolling process of steel is aforming techniquein which the material is rolled at temperatures below its recrystallization temperature. It is carried out between two or more rotating rollers.

Unlike hot rolling, which is performed at high temperatures, cold rolling is generally performed at room temperature.

In industry, materials to be cold rolled are usually delivered in the form of coils, which have been previously reduced by a hot rolling process.

The cold rolling process involves the Material preparation, including threading the coil into the rolling mill and removing waste and oxide through unwinding and pickling processes.

The material is then passed through the different rolling rollersdepending on the type of rolling mill used, such as two-roller, four-roller, six-roller, or multi-roller mills.

Each laminator configuration has its own advantages in terms of performance and stability.

Cold-rolled steel profiles

Within cold-rolled steel profiles, we find a wide variety of options to adapt to different applications and needs. These are some of the most commonly used:

Cold rolled angle

U Profile

Open profile

Handrail

A handrail is a profile designed to be held or used as a railing on stairs, balconies, and walkways.

Omega profile

Bericht Projects

Remember that at Bericht, as experts in metal parts, we are experts in cold-rolled steel, offering the highest quality solutions and providing the best advice to our customers.

- All

- Operation stamping

- Progressive stamping

- Welded insert assemblies

- Welded assemblies

- Assembled assemblies

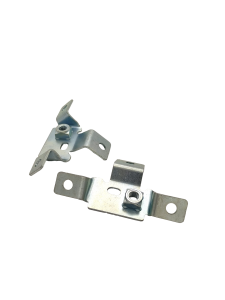

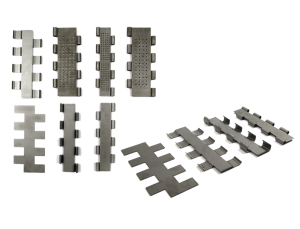

OEM: Volkswagen

Thickness: 4 mm

Annual production: 7.400

Surface treatment: Zinc

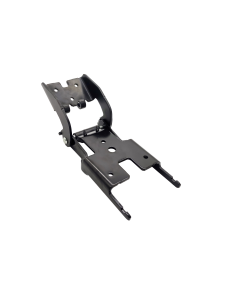

OEM: PSA

Material: DC01

Thickness: 1,5 mm

Anual production: 200.000

Surface treatment: Cataphoresis

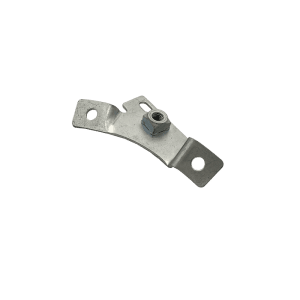

OEM: Renault

Material: DD13

Thickness: 3 mm

Annual production: 150.000

Surface treatment: Cataphoresis

OEM: Volkswagen

Material: S420MC

Thickness: 2,5 mm

Annual production: 14.800

Surface treatment: Cataphoresis

OEM: Renault

Material: DD13

Thickness: 3 mm

Annual production: 100.000

Surface treatment: Cataphoresis

OEM: Renault

Material: HC42LA

Thickness: 1 mm

Annual production: 200.000

Surface treatment: Cataphoresis

OEM: Renault trucks

Material: S420MC

Thickness: 1,5 mm

Annual production: 1.800

Surface treatment: Cataphoresis

OEM: Renault trucks

Material: S420MC

Thickness: 1,5 mm

Annual production: 1.800

Surface treatment: Cataphoresis

OEM: Renault

Material: DD13

Thickness: 3 mm

Annual production: 150.000

Surface treatment: Cataphoresis

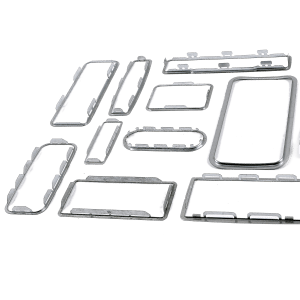

OEM: Daimler

Material: HC380LA

Thickness: 1,5 mm

Annual production: 200.000

Surface treatment: Cataphoresis

OEM: Volkswagen

Material: S355MC

Thickness: 4mm

Annual production: 1.100.000

OEM: Volkswagen

Material: S420MC

Thickness: 2 mm

Annual production: 7.400

Surface treatment: Zinc

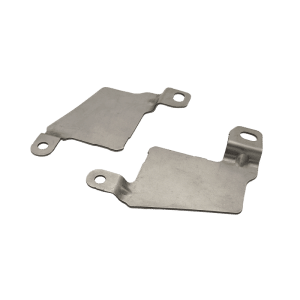

OEM: Volkswagen

Material: CR380LA

Thickness: 1,5 mm

Annual production: 300.000 (1+1)

SIPEJMA

Material: Varios (S275JR, St 33, S185, P355N)

Thickness: 3 / 8 mm

Annual production: varios

Surface treatment: Zinc

COMETEL

Material: Various (S275JR, DD11)

Thickness: 2 / 6 mm

Annual production: Various

Surface treatment: N/A

OEM: Ford, Volkswagen, Audi...

Material: Various (DX51D, DX52D)

Thickness: 0,5 / 0,7 mm

Annual production: Various

Surface treatment: Zinc

Discover our Advanced Metal Stamping Solutions

We help you create high-quality, precision metal parts tailored to your needs and budget. Download our portfolio of services and solutions and discover everything we can offer.