High-strength steels or high-yield steels

What are high-strength steels?

What material increases the yield strength of steels?

Which steel has greater elasticity?

The elasticity of a steel depends not only on its composition and heat treatment, but also on factors such as the microstructure, plastic deformation, and physical properties of the material.

What are the main characteristics of high yield strength steels?

High-strength steels have a number of characteristics that make them ideal for applications requiring high-strength and durable materials. The main characteristics of these steels include:

Properties of High Yield Strength Steels

Weldability.

Despite their high strength, they are weldable, making them easy to use in component manufacturing and assembly. It's important to follow proper techniques and procedures to ensure quality welding and avoid problems such as hydrogen-induced cracking.

High resistance

High-strength steels offer superior tensile strength, making them suitable for applications requiring heavy loads or extreme stresses. They are able to withstand stress without permanently deforming.

Good tenacity

They have high toughness, which means they can absorb energy without fracturing easily. This makes them ideal for applications where impact resistance is required. For example, they are used in the manufacture of pressure hulls or in the construction of nuclear submarines (HY steel).

Higher yield strength

They are characterized by having a higher yield strength than conventional steels. The yield strength is the maximum load a material can withstand without experiencing permanent deformation. High yield strength steels allow for the design of lighter and more efficient structures without compromising their strength.

Corrosion resistance

They are designed to offer greater corrosion resistance compared to conventional steels. This is especially important in aggressive or marine environments, where corrosion can compromise structural integrity.

Applications of high-strength steels

Automotive industry

High-strength steels are used in the manufacture of automotive structural components, such as bodies, chassis, and suspensions. These steels allow for lighter vehicle construction, contributing to reduced emissions and increased fuel efficiency.

Heavy machinery

They are used in the manufacture of heavy machinery, such as excavators, cranes, and agricultural equipment. These special steels make it possible to build stronger and more durable equipment, capable of withstanding heavy loads and demanding working conditions.

Weighing machineryAerospace industry

Manufacturing of structural components for aircraft and satellites. They offer a combination of strength and lightness, which contributes to improving aircraft efficiency and aerodynamic performance.

Construction and structures

Construction of bridges, high-rise buildings, and industrial structures. These steels allow for the design of lighter and thinner structures without compromising strength and safety.

Naval industry

Construction of boats and ships, providing structural strength and reducing the vessel’s overall weight. This improves its performance and fuel efficiency.

Bericht Projects

- All

- Operation stamping

- Progressive stamping

- Welded insert assemblies

- Welded assemblies

- Assembled assemblies

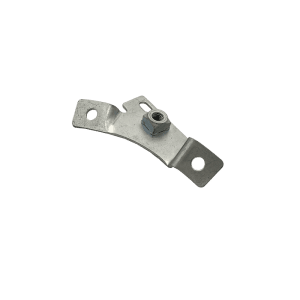

OEM: Volkswagen

Thickness: 4 mm

Annual production: 7.400

Surface treatment: Zinc

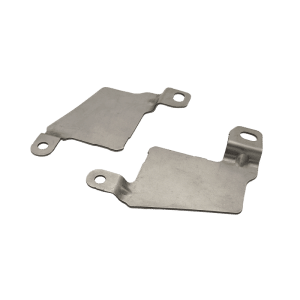

OEM: PSA

Material: DC01

Thickness: 1,5 mm

Anual production: 200.000

Surface treatment: Cataphoresis

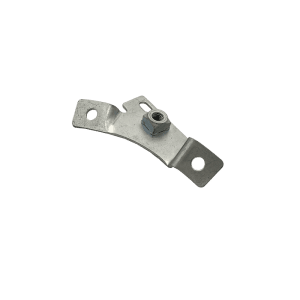

OEM: Renault

Material: DD13

Thickness: 3 mm

Annual production: 150.000

Surface treatment: Cataphoresis

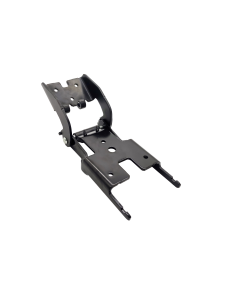

OEM: Volkswagen

Material: S420MC

Thickness: 2,5 mm

Annual production: 14.800

Surface treatment: Cataphoresis

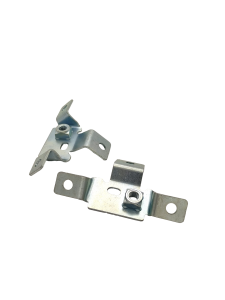

OEM: Renault

Material: DD13

Thickness: 3 mm

Annual production: 100.000

Surface treatment: Cataphoresis

OEM: Renault

Material: HC42LA

Thickness: 1 mm

Annual production: 200.000

Surface treatment: Cataphoresis

OEM: Renault trucks

Material: S420MC

Thickness: 1,5 mm

Annual production: 1.800

Surface treatment: Cataphoresis

OEM: Renault trucks

Material: S420MC

Thickness: 1,5 mm

Annual production: 1.800

Surface treatment: Cataphoresis

OEM: Renault

Material: DD13

Thickness: 3 mm

Annual production: 150.000

Surface treatment: Cataphoresis

OEM: Daimler

Material: HC380LA

Thickness: 1,5 mm

Annual production: 200.000

Surface treatment: Cataphoresis

OEM: Volkswagen

Material: S355MC

Thickness: 4mm

Annual production: 1.100.000

OEM: Volkswagen

Material: S420MC

Thickness: 2 mm

Annual production: 7.400

Surface treatment: Zinc

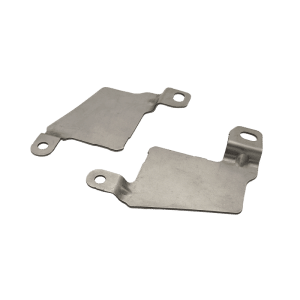

OEM: Volkswagen

Material: CR380LA

Thickness: 1,5 mm

Annual production: 300.000 (1+1)

SIPEJMA

Material: Varios (S275JR, St 33, S185, P355N)

Thickness: 3 / 8 mm

Annual production: varios

Surface treatment: Zinc

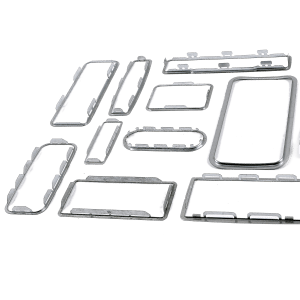

COMETEL

Material: Various (S275JR, DD11)

Thickness: 2 / 6 mm

Annual production: Various

Surface treatment: N/A

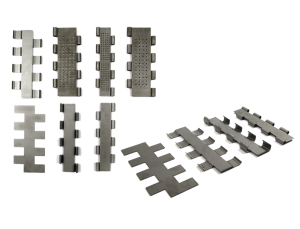

OEM: Ford, Volkswagen, Audi...

Material: Various (DX51D, DX52D)

Thickness: 0,5 / 0,7 mm

Annual production: Various

Surface treatment: Zinc

Discover our Advanced Metal Stamping Solutions

We help you create high-quality, precision metal parts tailored to your needs and budget. Download our portfolio of services and solutions and discover everything we can offer.