Cold stamping

What is cold stamping?

Cold stamping is a manufacturing process that involves deforming a material without heating it above its recrystallization temperature. This makes it possible to create more complex parts with greater precision.

It is used to manufacture metal or alloy parts from thin sheets or strips of metal.

What is the importance of cold stamping?

The cold stamping method uses a press to transform the metal without using heat. Its importance lies in the high precision it offers with tight tolerances. This is essential in various industrial applications, such as the automotive, aerospace, electronics, and construction sectors, among others.

In addition, it is an efficient and cost-effective procedure for mass production. Thanks to this, a large volume of parts can be produced in a short time. It should also be noted that this technique does not generate toxic waste, making it one of the most environmentally friendly manufacturing processes.

What is the cold stamping process?

Phases of cold stamping

Preparation of raw materials

The cold stamping process begins with the preparation of the raw material, which can be a sheet or strip of metal.

Stamping press

This sheet or strip of metal is then placed in a cold-forming press, which uses a combination of mechanical pressure and shear to deform the material into the desired shape.

Matrix

The material is deformed using a die with a specific shape attached to the press. The die can be simple or complex depending on the shape of the desired part.

Metal deformation

The press uses a compressive force to apply pressure to the die, which deforms the sheet or strip metal into the shape of the die.

Removing the part

The stamped part is then removed from the die, usually by an ejection mechanism.

How long does it take to make a cold stamping?

The duration of cold stamping depends on various factors, such as the complexity of the part, its size, material, the die, etc. Typically, this process can take from a few seconds to minutes. It is a fast and efficient process.

However, there are some factors that can interfere with the process, even delaying it. This is the case with ambient temperature, since at very low temperatures the metal becomes brittle and can break or crack. Other factors that can affect the duration of the cold stamping process include:

- Thickness of the material.

- Strength of the material.

- Surface finish.

- The die.

- Operator skill.

With all these capabilities, combined with their expertise and know-how, Bericht is the perfect partner for creating metal parts for sectors such as the automotive and white goods industries. We have extensive experience in the metal stamping process, and our team uses the latest technology to achieve high-quality, precise results for every project.

What are the benefits of cold stamping?

Cold stamping has many advantages, and in this article we will explain the main ones.

A better quality product

Cold stamping allows for the manufacture of highly precise, close-tolerance parts. This manufacturing method can be used to produce high-quality parts with a superior surface finish. It can also strengthen the material, as it can improve the strength and hardness of the part, which can be especially beneficial for parts that require high strength and durability. Furthermore, cold stamping can reduce part distortion, as the material is not subjected to high temperatures that can cause distortion or expansion.

A wide range of materials

Cold stamping can be used to form a wide variety of materials, including metals, alloys, plastics, and composites, allowing for the creation of a variety of designs. In the automotive industry, this technology can be used to produce body parts such as doors, fenders, hoods, trunks, and sills; chassis components such as engine mounts, body reinforcements, cross members, and anti-roll bars; suspension parts such as wishbones, steering rods, and torsion bars; and transmission parts such as gearboxes; chassis components such as engine mounts, body reinforcements, cross members, and anti-roll bars.

An economic advantage

Cold stamping is typically less expensive than other manufacturing methods because it does not require heating the material, which can reduce energy costs.

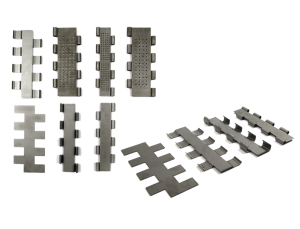

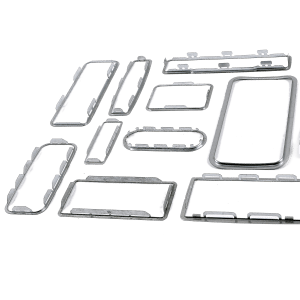

Bericht Projects

At Bericht, we can help you with your cold stamping projects. We manufacture small and medium-sized metal parts, primarily for the household appliance and automotive sectors. All of this is tailored to our clients’ requirements. If you’re looking for a great metal stamping service, don’t hesitate to contact us!

- All

- Operation stamping

- Progressive stamping

- Welded insert assemblies

- Welded assemblies

- Assembled assemblies

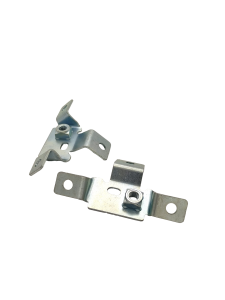

OEM: Volkswagen

Thickness: 4 mm

Annual production: 7.400

Surface treatment: Zinc

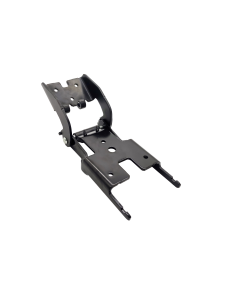

OEM: PSA

Material: DC01

Thickness: 1,5 mm

Anual production: 200.000

Surface treatment: Cataphoresis

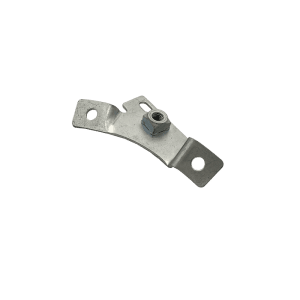

OEM: Renault

Material: DD13

Thickness: 3 mm

Annual production: 150.000

Surface treatment: Cataphoresis

OEM: Volkswagen

Material: S420MC

Thickness: 2,5 mm

Annual production: 14.800

Surface treatment: Cataphoresis

OEM: Renault

Material: DD13

Thickness: 3 mm

Annual production: 100.000

Surface treatment: Cataphoresis

OEM: Renault

Material: HC42LA

Thickness: 1 mm

Annual production: 200.000

Surface treatment: Cataphoresis

OEM: Renault trucks

Material: S420MC

Thickness: 1,5 mm

Annual production: 1.800

Surface treatment: Cataphoresis

OEM: Renault trucks

Material: S420MC

Thickness: 1,5 mm

Annual production: 1.800

Surface treatment: Cataphoresis

OEM: Renault

Material: DD13

Thickness: 3 mm

Annual production: 150.000

Surface treatment: Cataphoresis

OEM: Daimler

Material: HC380LA

Thickness: 1,5 mm

Annual production: 200.000

Surface treatment: Cataphoresis

OEM: Volkswagen

Material: S355MC

Thickness: 4mm

Annual production: 1.100.000

OEM: Volkswagen

Material: S420MC

Thickness: 2 mm

Annual production: 7.400

Surface treatment: Zinc

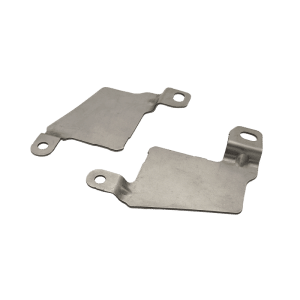

OEM: Volkswagen

Material: CR380LA

Thickness: 1,5 mm

Annual production: 300.000 (1+1)

SIPEJMA

Material: Varios (S275JR, St 33, S185, P355N)

Thickness: 3 / 8 mm

Annual production: varios

Surface treatment: Zinc

COMETEL

Material: Various (S275JR, DD11)

Thickness: 2 / 6 mm

Annual production: Various

Surface treatment: N/A

OEM: Ford, Volkswagen, Audi...

Material: Various (DX51D, DX52D)

Thickness: 0,5 / 0,7 mm

Annual production: Various

Surface treatment: Zinc

Discover our Advanced Metal Stamping Solutions

We help you create high-quality, precision metal parts tailored to your needs and budget. Download our portfolio of services and solutions and discover everything we can offer.