Hot-rolled steel

Hot-rolled steel: process, types and applications

Hot-rolled steel is an important process in the steel industry, which involves subjecting raw materials to high temperatures to shape them and improve their properties.

At Bericht, we are experts in this process and understand all its attributes and advantages. If you need personalized advice on the processing of metal parts, contact us.

Hot-rolled steel

Hot-rolled steel is a manufacturing method that involves heating the steel billet to high temperatures and then passing it through rollers to shape it.

During this process, the steel undergoes plastic deformation, making it more malleable and giving it improved mechanical properties.

Hot-rolled steel: material and alloys

Hot-rolled steel can be manufactured using different materials and alloys, giving it specific properties. Some of the most common alloys used in the process are low-carbon steel, formed steel, and conventional steel.

Other alloys may include elements such as carbon, manganese, silicon, nickel, chromium, and others. Each alloy has a particular effect on the steel’s characteristics, such as strength, ductility, and corrosion resistance. These alloys are added to steel during the manufacturing process to improve its strength, hardness, and other mechanical characteristics.

Types of hot-rolled steel

Hot-rolled low-carbon steel

Hot-rolled low-carbon steel is widely used in the construction industry due to its high ductility and ease of forming. This type of steel is ideal for the manufacture of structural profiles and architectural components, such as pipes and beams.

Conventional hot-rolled steel

Conventional hot-rolled steel is valued in the industry for its strength and versatility. It is suitable for structural applications, pipe fabrication, and other uses requiring superior strength.

Hot-rolled formed steel

Hot-rolled formed steel is used in projects requiring a specific and complex shape. This type of steel is commonly used in the manufacture of components for machinery, automobiles, and industrial equipment.

Hot-rolled electrogalvanized steel

Electrogalvanized steel manufactured using the hot-rolling process combines the advantages of both processes. First, the steel undergoes hot rolling to shape it and improve its properties. Then, an electrogalvanized coating is applied to provide additional corrosion protection, making it ideal for applications requiring strength and durability in harsh environments. The resulting hot-rolled steel has a galvanized finish and improved properties.

Custom hot rolled stainless steel

Hot-rolled steel process

Hot-rolled steel and its applications

Hot-rolled steel has a wide range of applications in various industrial sectors. Some of the most common uses include:

Construction of infrastructure

It is used in the construction of bridges, buildings, transmission towers, and other structures that require strength and durability.

Vehicle manufacturing

This type of steel is used in the production of cars, trucks, ships, and other vehicles due to its strength and impact absorption capacity, in addition to the possibility of electrogalvanizing.

Renewable energy

Wind turbines and other renewable energy structures benefit from hot-rolled steel due to its strength and ability to withstand environmental conditions.

Household appliances

It is found in household appliances such as refrigerators, washing machines, and stoves, thanks to its strength and ease of forming.

This raw material has many benefits in terms of processing, dimensional tolerances, material strength and surface finish. Itscontrolled roughness allows for better adhesion of coatings, such as galvanizing, and facilitates additional operations such as cutting or welding.

Other varieties, such as hot-rolled round steel, can be used in construction, machinery manufacturing, and other applications requiring cylindrical components.

Hot-rolled steel: differences with cold-rolled steel

Advantages of hot-rolled steel

The use of hot-rolled steel offers several significant advantages. Some of these advantages include:

Good corrosion resistance

Good ductility and toughness

Forming capacity

Rough surface that facilitates adhesion

Greater strength and hardness

Lower risk of damage during handling and installation

At Bericht, we offer a wide variety of hot-rolled steel to meet our customers’ needs. If you’re looking for an expert hot-rolled steel supplier, don’t hesitate to contact us. We’ll be happy to help you find the right solution for your needs.

Bericht Projects

Remember that at Bericht, as experts in metal parts, we are experts in cold-rolled steel, offering the highest quality solutions and providing the best advice to our customers.

- All

- Operation stamping

- Progressive stamping

- Welded insert assemblies

- Welded assemblies

- Assembled assemblies

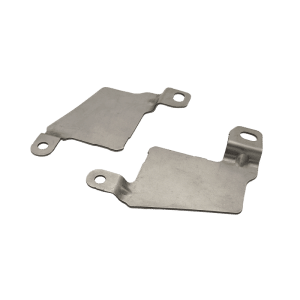

OEM: Volkswagen

Thickness: 4 mm

Annual production: 7.400

Surface treatment: Zinc

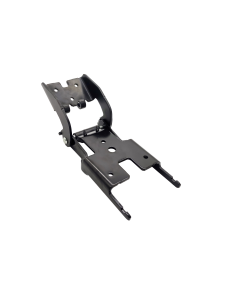

OEM: PSA

Material: DC01

Thickness: 1,5 mm

Anual production: 200.000

Surface treatment: Cataphoresis

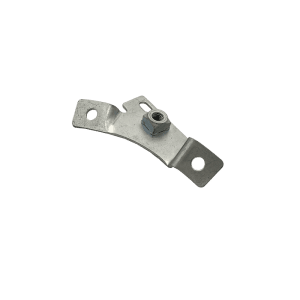

OEM: Renault

Material: DD13

Thickness: 3 mm

Annual production: 150.000

Surface treatment: Cataphoresis

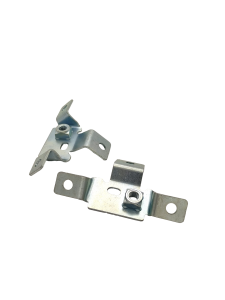

OEM: Volkswagen

Material: S420MC

Thickness: 2,5 mm

Annual production: 14.800

Surface treatment: Cataphoresis

OEM: Renault

Material: DD13

Thickness: 3 mm

Annual production: 100.000

Surface treatment: Cataphoresis

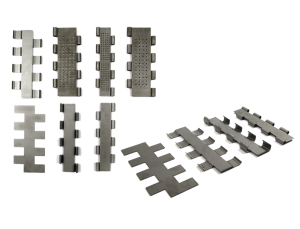

OEM: Renault

Material: HC42LA

Thickness: 1 mm

Annual production: 200.000

Surface treatment: Cataphoresis

OEM: Renault trucks

Material: S420MC

Thickness: 1,5 mm

Annual production: 1.800

Surface treatment: Cataphoresis

OEM: Renault trucks

Material: S420MC

Thickness: 1,5 mm

Annual production: 1.800

Surface treatment: Cataphoresis

OEM: Renault

Material: DD13

Thickness: 3 mm

Annual production: 150.000

Surface treatment: Cataphoresis

OEM: Daimler

Material: HC380LA

Thickness: 1,5 mm

Annual production: 200.000

Surface treatment: Cataphoresis

OEM: Volkswagen

Material: S355MC

Thickness: 4mm

Annual production: 1.100.000

OEM: Volkswagen

Material: S420MC

Thickness: 2 mm

Annual production: 7.400

Surface treatment: Zinc

OEM: Volkswagen

Material: CR380LA

Thickness: 1,5 mm

Annual production: 300.000 (1+1)

SIPEJMA

Material: Varios (S275JR, St 33, S185, P355N)

Thickness: 3 / 8 mm

Annual production: varios

Surface treatment: Zinc

COMETEL

Material: Various (S275JR, DD11)

Thickness: 2 / 6 mm

Annual production: Various

Surface treatment: N/A

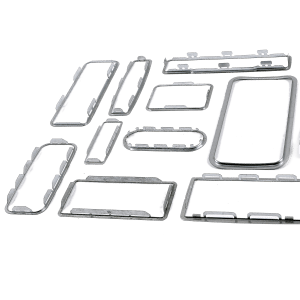

OEM: Ford, Volkswagen, Audi...

Material: Various (DX51D, DX52D)

Thickness: 0,5 / 0,7 mm

Annual production: Various

Surface treatment: Zinc

Discover our Advanced Metal Stamping Solutions

We help you create high-quality, precision metal parts tailored to your needs and budget. Download our portfolio of services and solutions and discover everything we can offer.