Zinc coating is an industrial process in which metal parts are coated with zinc to protect them from corrosion and rust. This process also provides metals with a more aesthetic appearance and is used in numerous industries.

At Bericht we are experts in the manufacturing of metal parts. We understand how this process works and its benefits, which is why we explain it in detail in this article.

What is zinc coating?

Zinc coating is a metal finishing process used to protect metal parts from corrosion and rust. It involves applying a layer of zinc to the surface of the metal, creating a protective barrier between the base metal and the external environment.

This layer acts as a sacrificial layer, meaning it will corrode before the base metal does, thereby prolonging the service life of the part and keeping it in optimal condition. This process is used in various industries, from construction to automotive, as it gives metal parts extra protection, making them much more durable.

Zinc coating process

The process of providing metal parts with an extra layer of protection is carried out in several stages, as detailed below:

- Surface preparation: the part undergoes a thorough cleaning process to remove any dirt, rust, or contaminants that could affect the adhesion of the zinc.

- Pickling: in this stage, the part is immersed in an acid solution to remove any rust and prepare the surface for coating.

- Galvanizing: the part is immersed in a bath of molten zinc at high temperature, generally around 450 °C. The zinc adheres to the metal surface, forming a protective layer.

- Cooling and drying: once the part has been coated with zinc, it is removed from the bath and cooled to solidify the coating. A sealer may then be applied to improve the durability and corrosion resistance of the zinc coating.

This process is performed meticulously to ensure metals are fully protected against corrosion, granting them a longer lifespan and greater resistance to harsh environmental conditions.

Benefits of zinc coating

This zinc coating process offers numerous benefits to the parts subjected to it. Among these benefits, the following stand out:

- Corrosion protection: the zinc layer acts as an effective barrier against moisture, oxygen, and other corrosive agents.

- Increased durability: zinc-coated parts have a prolonged lifespan due to their resistance to corrosion and wear.

- Low maintenance: by reducing the risk of corrosion, the parts require less maintenance and retain their appearance for longer.

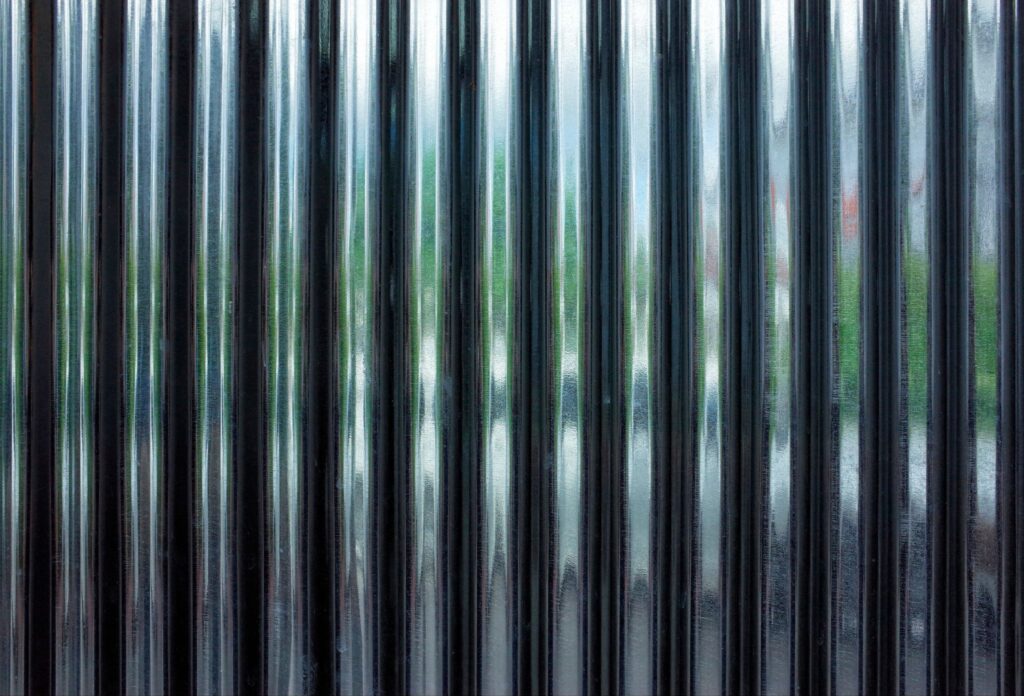

- Aesthetic appearance: the zinc finish provides a bright and uniform look, enhancing the appearance of metal parts.

- Coating compatibility: metals that undergo this procedure can receive additional paints and coatings to further enhance their appearance and protection.

This coating process is essential in numerous industries, from construction to vehicle manufacturing and the maritime industry, as most components often require extra corrosion protection.

Industrial applications of zinc coating

Zinc coating is a finishing process that offers effective protection against corrosion and wear for multiple industrial applications. By applying a layer of zinc to metal surfaces, a protective barrier is created that prolongs the service life of components and structures.

- Construction: widely used to protect metal structures exposed to adverse environmental conditions. From beams and columns to railings and roofs, it provides lasting protection against corrosion in buildings, bridges, transmission towers, and other infrastructure.

- Automotive: components and metal parts used in vehicle manufacturing also use this process. From bodywork and chassis to bolts and structural components, zinc coating helps prevent oxidation and premature deterioration, contributing to vehicle durability and safety.

- Home appliances and electronics: in the manufacturing of appliances like washing machines, refrigerators, and ovens, as well as in electronic devices such as computers and mobile devices, it is used to protect metal parts from corrosion caused by exposure to moisture and other environmental factors.

- Naval industry: in maritime environments, where metal structures are constantly exposed to saltwater and humidity, this zinc bath is essential for protecting ships, ports, docks, and other marine equipment from corrosion and wear.

- Agricultural equipment: in agricultural machinery such as tractors, plows, and harvesters, it protects metal parts from corrosion caused by exposure to soil, moisture, and agricultural chemicals.

- Chemical and petrochemical industry: equipment and piping used in these sectors are exposed to corrosive environments. This process provides a protective layer that extends the service life of these components and prevents premature corrosion.

As we’ve seen, the process of coating metal parts with a layer of zinc protects them from the elements and provides extra strength and durability.